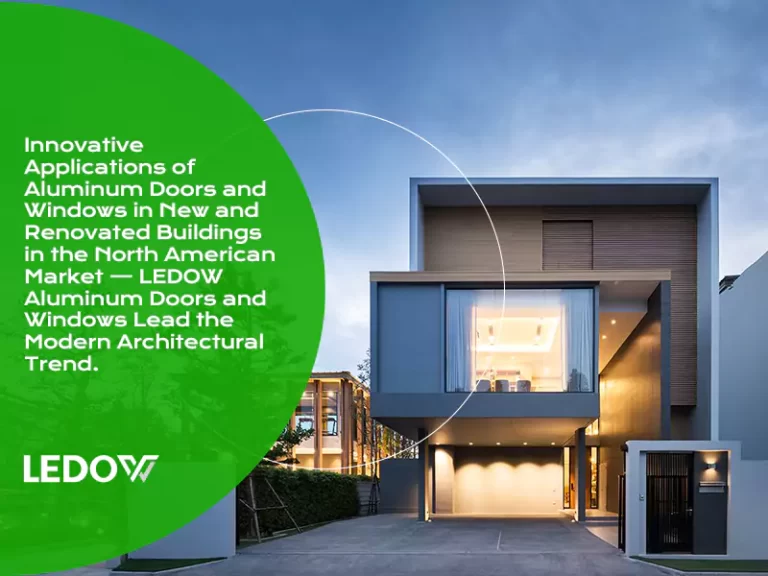

As the demands for aesthetics, comfort, energy efficiency, and security in construction increase, aluminum windows and doors have emerged as a must-have in modern architecture, thanks to their unique advantages. Today, we will dive into the material properties, sophisticated design, energy-saving effects, and market potential of aluminum windows and doors, answering the question: “Why are aluminum windows and doors the best choice for your construction projects?”

1. The Material Characteristics of Aluminum Windows and Doors: The Secret to Lightness, Strength, and Durability

Lightness and High Strength

Compared to traditional wooden and PVC windows, aluminum offers significant advantages. First, aluminum is lighter, making installation and transportation more efficient. Secondly, aluminum has high strength, able to withstand significant external forces, ensuring the stability of the windows and doors.

In coastal and humid areas, aluminum’s corrosion resistance is particularly advantageous. Wooden windows can suffer from rot due to moisture, while PVC windows may deform after prolonged exposure to the sun. In contrast, aluminum undergoes special surface treatments to resist weather conditions, providing a longer lifespan.

“Black Tech” of Thermal Break Aluminum: Heat Isolation for Improved Energy Efficiency

Thermal break aluminum windows and doors represent a groundbreaking technology in the industry. By adding an insulating strip in the middle of the aluminum profile, they effectively block heat transfer, significantly reducing the building’s energy consumption. For example, in a typical aluminum window, heat and cold can easily pass through the frame, whereas thermal break aluminum isolates outdoor temperatures, maintaining a stable indoor environment.

Using thermal break aluminum windows in a home can save 15%-30% in annual air conditioning costs, reducing energy expenses and enhancing overall comfort.

2. The Structural Design of Aluminum Windows and Doors: Quality Through Detail

Profile Thickness and Load-Bearing Capacity

The thickness of the profiles directly impacts the load-bearing capacity of the windows and doors. In high-rise buildings, the profile thickness of aluminum windows generally needs to be at least 2.0mm to withstand external wind pressure, earthquakes, and other natural factors. For low-rise buildings, 1.4mm thickness is sufficient to provide adequate support.

Glass Configuration: Noise Isolation and UV Protection

Modern aluminum windows and doors commonly use double-glazed glass to reduce noise. For instance, a 5mm thick double-glazed glass can achieve a noise reduction of 30-35 decibels, effectively blocking external noise and providing a quieter living environment.

Additionally, Low-E glass has a UV-blocking rate of over 99%, effectively preventing the fading and aging of interior furniture and flooring by blocking harmful ultraviolet rays.

Surface Treatment: Aesthetic and Durability Assurance

Electrophoresis, spray coating, and wood grain transfer are common surface treatment processes for aluminum windows and doors. Among them, electrophoresis offers the best weather resistance. After five years of testing, the color of the aluminum window remains almost unchanged, while spray coating and wood grain transfer are more economical but may fade when exposed to outdoor conditions over time. Different surface treatment options allow for a balance between aesthetics and durability, catering to various consumer needs.

Hidden Drainage Design: Avoiding Water Accumulation Hazards

Traditional windows and doors often face water accumulation problems, particularly in areas with high rainfall. Modern aluminum windows incorporate a hidden drainage system, cleverly integrated into the structure, which not only improves aesthetics but also effectively prevents corrosion and safety hazards caused by water accumulation.

3. Custom Solutions for Different Customer Needs

For Dealers: High Turnover Rate and Zero Inventory Pressure

The aluminum window market is growing at an annual rate of approximately 15%, making it crucial for dealers to choose high-turnover products to ensure profitability. The flexible custom production model of aluminum windows allows for quick delivery within 7 days, reducing inventory pressure. Dealers can also choose popular models tailored to regional demands, enhancing their market competitiveness.

For Builders: Shorter Construction Time, Reduced Costs

Facing tight construction schedules and budget constraints, builders benefit from standardized aluminum window products that allow for quick installation and prevent delays in project progress. The full measurement and installation services ensure that windows are accepted on the first inspection, minimizing the risk of rework.

For Self-Builders: Small Investment, Big Impact

For self-builders, customized aluminum windows not only enhance the comfort of the living space but also significantly increase the visual appeal of the house. Especially with the choice of narrow frame designs, a home can look more modern and stylish, without a substantial increase in cost.

4. Energy-Efficiency and Security Benefits of Aluminum Windows: Data-Driven Competitive Advantage

Energy-Saving Economics

Compared to regular aluminum windows, thermal break aluminum windows significantly reduce the load on air conditioning systems, saving about 30% in energy costs. For example, in a 100-square-meter home, annual air conditioning costs can be reduced by approximately $120-$180. This energy-saving advantage not only lowers operating costs but also boosts the building’s environmental performance.

Security Upgrades

Aluminum windows can be optionally equipped with built-in anti-theft grilles, enhancing security without compromising aesthetics. Paired with anti-pry hardware, these windows can effectively increase security. According to actual test data, anti-pry hardware can withstand more than 1500N of external force, ensuring the safety of the home.

5. Trust Backing: Let the Data Speak

Visualizing Factory Strength

Modern production factories are equipped with CNC processing centers and automated spray coating lines, ensuring that every detail of the aluminum windows is precisely processed and quality-controlled. The factory has an annual production capacity of up to 300,000 square meters, capable of meeting the needs of large-scale projects.

Certification Wall

Our aluminum windows have received various certifications, including energy efficiency certifications from export countries, ISO 9001 quality management system certification, NFRC, NAMI, and Energy Star certifications. We also maintain long-term partnerships with industry-leading aluminum suppliers. These authoritative certifications provide strong assurances of product quality.

User Testimonials

One of our dealers has been working with us for over five years, with no returns or complaints during this period. Numerous self-building homeowners have shared installation videos showcasing the excellent performance of aluminum windows in real-world applications, earning widespread praise.

Conclusion

With their outstanding performance and wide range of applications, aluminum windows have become an indispensable part of modern architecture. Whether it’s for energy efficiency, noise reduction, corrosion resistance, or the convenience of design and installation, aluminum windows can offer long-term value for your building project. If you’re still hesitating, choosing aluminum windows means choosing the future of your living and working space.